We have been designing and manufacturing gaskets for 50 years. We focus on this product because the world of seals is mainly invisible to the eye, yet it is essential for the operation of any mechanical, mechatronic or electronic system.

From the very beginning, we have been bringing quality into the seals industry, where attention to detail and technological progress are central to the performance and reliability of every device.

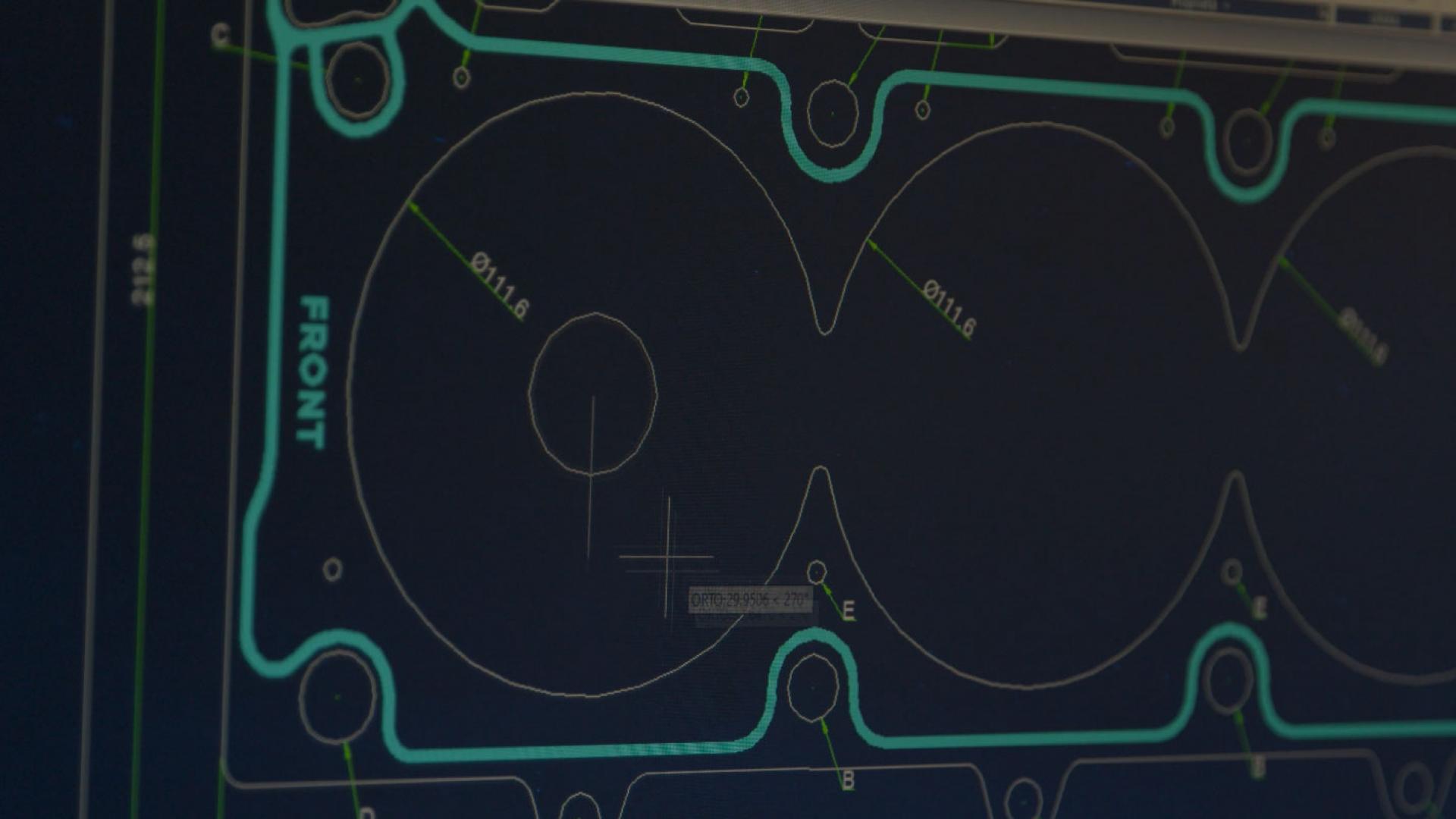

Product design and the production process take place on our general headquarters, where we use 3D and FEM modelling software as well as numerous laboratory tests and material analyses to optimise seal morphology and to be sure we always offer the right solution.

Our products can be sent to any destination, thanks to a widespread global network of production plants.

CUSTOMER NEEDS

Seals, Co-Engineering and Customers' needs

We always start with your actual requirements so that we can work together on the range of application, the fluid in question, pressures, temperatures, external environment, and the static and dynamic stresses on the structures and components the seal needs to couple with.

ANALYSIS

Choice of materials

We constantly work to source the best materials to meet the different application needs and withstand thermal and mechanical stresses.

The choice of the best raw materials for the specific application is a strategic step when it comes to configuring a seal, since it makes it possible to achieve the required performance in terms of cost and quality.

Every application needs different characteristics. Athena has the right solution to solve any seal problems.

DEVELOPMENT

The most important stages in gaskets' development

- INITIAL PROTOTYPES: At this stage we carry out the initial functional tests and try out the future potential of the product,

- ADVANCED PROTOTYPES: The prototype begins to mature and approach the definitive version of the project,

- PRE-PRODUCTION SERIES: In this stage, the seals are made using mass production equipment; at the same time, we perfect the production process,

- MASS PRODUCTION: It is the result of experience gained during the three previous stages: now the seal is optimised both as a product and as a production process, and is ready to be released on the market.

Discover the various types of gaskets that Athena Industries produces, including insulating gaskets, gaskets for water pumps and gaskets for boilers.

Applications and Case History

Applications

Boilers, heat pumps, heating

Applications

Hydraulics and pumps

Applications

Air & refrigerator compressors

Applications

Bicycles, motorcycles and motors

Applications

Agricultural machinery and off-highway equipment

Applications

Food, medical and pharmaceutical industry

Applications